System Startup

Initial Checks

Section titled “Initial Checks”Before proceeding with system startup, ensure all plumbing and wiring is complete. Verify the following:

- E-Stop is pushed in

- DFU is connected to 120V circuit

- Circuit breakers inside unit are on

- Allow 30-60 seconds for system boot up when powered on

- Scan QR code on unit to access the FullShop app

High-Level Startup Sequence

Section titled “High-Level Startup Sequence”%%{init: {'theme': 'base', 'themeVariables': { 'primaryColor': '#ffffff', 'primaryTextColor': '#1c6b92', 'lineColor': '#6d6e71', 'secondaryColor': '#8eaec9', 'tertiaryColor': '#c64527'}}}%%

graph TD

A([Start]) --> B

B[Confirm Plumbing & Wiring]

B --> C[Power Up DFU]

C --> D[Connect DFU to Wi-Fi]

D --> E[Power Up SVI]

E --> F[Add SVIs to Mesh Network]

F --> G[Bleed Water Header]

G --> H[Bleed Coolant Header]

H --> I[Setup SVIs in App]

I --> J[Validate at each CNC]

J --> K([System Ready])

style A fill:#1c6b92,stroke:#1c6b92,color:#ffffff

style B fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style C fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style D fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style E fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style F fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style G fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style H fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style I fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style J fill:#ffffff,stroke:#1c6b92,color:#1c6b92

style K fill:#1c6b92,stroke:#1c6b92,color:#ffffff

Detailed Process Steps

Section titled “Detailed Process Steps”1. Confirm Plumbing & Device Wiring

Section titled “1. Confirm Plumbing & Device Wiring”- Has plumbing professional double checked and proofed the work? Confirmed & Signed Off

- Has electrical professional double checked and proofed their work? Confirm & Signed Off

2. DFU Power Up and Wi-Fi Connection

Section titled “2. DFU Power Up and Wi-Fi Connection”Power Setup

Section titled “Power Setup”- Before plugging in, confirm DFU Mesh physical address switches are as intended. View switch settings

- Turn ON 3-AMP breaker > Turn OFF 10-AMP breaker

- Plug in to 120V, this will power your device

App Configuration

Section titled “App Configuration”- Using app: Settings > DFU setup > Select DFU > Name DFU > Parameterize DFU > Save

- Using USB cable, connect DFU to PC with Google Chrome. Use left-most USB-C port inside DFU electrical enclosure

Wi-Fi Setup

Section titled “Wi-Fi Setup”- Using app: Settings > DFU setup > Select DFU > Configure DFU Wi-Fi > follow instructions

- While proceeding, confirm the Wi-Fi to DFU is established. 3 ways to confirm:

- External LED will go from white to blue

- Internal string LED labeled L2 will be blue

- App shows sync status via icon at upper right corner. May require refresh.

3. SVI Power Up

Section titled “3. SVI Power Up”- Before plugging in, confirm SVI Mesh physical address switches match as intended. View switch settings

- Before plugging in, confirm IDENTITY Switch is OFF (pushed up).

- Leave covers off for future steps.

- Plug in 120 V adapter to power device.

4. Add all SVI ‘s to mesh network with app

Section titled “4. Add all SVI ‘s to mesh network with app”- Using app: Settings > DFU Setup > Select DFU > Use CLICK TO ADD to add all Unrecognized SVIs

5. Water Header: Bleed Trapped Air

Section titled “5. Water Header: Bleed Trapped Air”- Turn ON 10-AMP breaker and clear any DFU errors.

- START WATER FLOW: Using the app: DFU Details > Select DFU > DFU Settings > Bleed out Air > Move Water Bleed selection to “Water Flowing”. Confirm pressure is being made using water pressure gauge.

- Physically go to each SVI and use IDENTITY switch to open fill valve. Once water is flowing and air looks bled out close valve with IDENTITY switch.

- If you installed an additional manual bleed out valves, open / close to bleed any remaining trapped air.

- STOP WATER FLOW: Using the app: DFU Details > Select DFU > DFU Settings > Bleed out Air > Move Water Bleed selection to “Standby” - CONFIRM WATER PRESSURE IS DROPPED BEFORE PROCEEDING

6. Coolant Header: Bleed Trapped Air

Section titled “6. Coolant Header: Bleed Trapped Air”- Turn ON 10-AMP breaker and clear any DFU errors.

- Physically go to closest manual bleed out valve, open to allow air escape. Bring container or hose to catch any oil that escapes from bleeding process.

- START COOLANT FLOW: Using app: DFU Details > Select DFU > DFU Settings > Bleed out Air > Move Coolant Bleed selection to “Pump Coolant” Initial speed setting is 1% - slow increase flow. No need to rush as pipes typically fill quickly. Confirm pressure is being made using coolant pressure gauge.

- Once coolant is flowing and air looks bled out close manual bleed valve while quickly proceeding to next step.

- STOP COOLANT FLOW: Using app: DFU Details > Select DFU > DFU Settings > Bleed out Air > Move Coolant Bleed selection to “Standby”

- Proceed to next closets bleed valve and repeat above steps at EVERY location where trapped air could be.

- When finished at all bleed locations

- CONFIRM in app that both Coolant bleed and Water bleed are in Standby

- CONFIRM COOLANT PRESSURE IS DROPPED BEFORE PROCEEDING

7. Setup each SVI with app

Section titled “7. Setup each SVI with app”- Physically go to first CNC machine – turn IDENTITY switch to ON position (down)

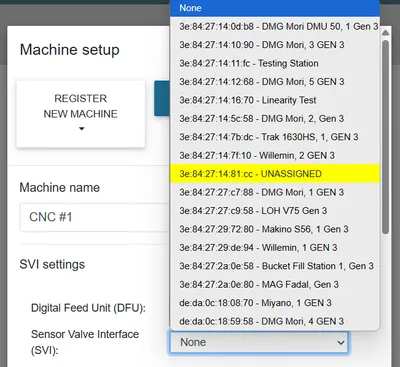

- Using app: Settings > Machine Setup > Select Machine > Select REGISTER NEW MACHINE at top of list

- Name machine as you refer to it in the shop (example Mill 43, DMG-Mori #4, ect.)

- Select DFU this SVI pairs with. Many shops only have a single DFU.

- Select the highlighted SVI and confirm MAC address on PCB (see below example)

- Using app: Complete required entries and selections when completed click REGISTER NEXT at top of page.

- At this CNC machine turn IDENTITY switch to OFF position (up)

- Repeat above step at each CNC until all SVIs are in the app paired to correct DFU.

- Use SAVE at top of app and return to summary page, review to confirm machines appear as expected.

- When finished – all SVI should be disabled and ready to validate.

- Reset any alarms that may have triggered at power up – may require 2 attempts to clear at first power up.

8. Validate at each CNC

Section titled “8. Validate at each CNC”- Physically go to first CNC. Double check IDENTITY switch is OFF (up position).

- Pull Level Sensor from Sump to purposely trigger low warning and low alarm – confirming wiring and sensor.

- Reset level sensor alarms that triggered. May require 2 attempts to clear at first power up.

- Repeat at all other CNC on the application.