Digital Feed Unit (DFU)

The DFU has several connections: electrical, internet and fluids. For fluids this includes water supply, water out, coolant supply, and coolant out ports on the unit. View connection diagram

Physical Mounting

Section titled “Physical Mounting”Location Requirements

Section titled “Location Requirements”- Considerations for location in the building:

- Typically, a centralized location of your plant works well where the unit can reach the most CNCs in the least amount of plumbing

- Locate where a coolant source (barrel, tote, etc) is easily accessible and can be changed out

- Locate where services such as water, power, and internet are established or can be

Wall Mounting Guidelines

Section titled “Wall Mounting Guidelines”- Considerations for mounting on a wall:

- Physical size and mounting are documented in our drawing section of manual

- Position DFU about 5.5 - 6 feet high on wall as we have found this height range is the best overall for any maintenance or inspections needed

- Provide clearance of at least 36 inches for ease of access and troubleshooting

- DFU weighs approx. 55 pounds, make sure your chosen mounting location can accommodate this

- Mount on wall with no or very low vibration

- Consider access for plumbing

- Installation of ball valves for the water supply, water output, and coolant output ports in case of quick shut off

Electrical Supply

Section titled “Electrical Supply”- 120VAC/15amp source required to power Digital Feed Unit

- DFU uses and IEC style receptacle if you want to source longer cable

Level Sensor - Monitors coolant supply

Section titled “Level Sensor - Monitors coolant supply”- Components provided in kit - View Kit

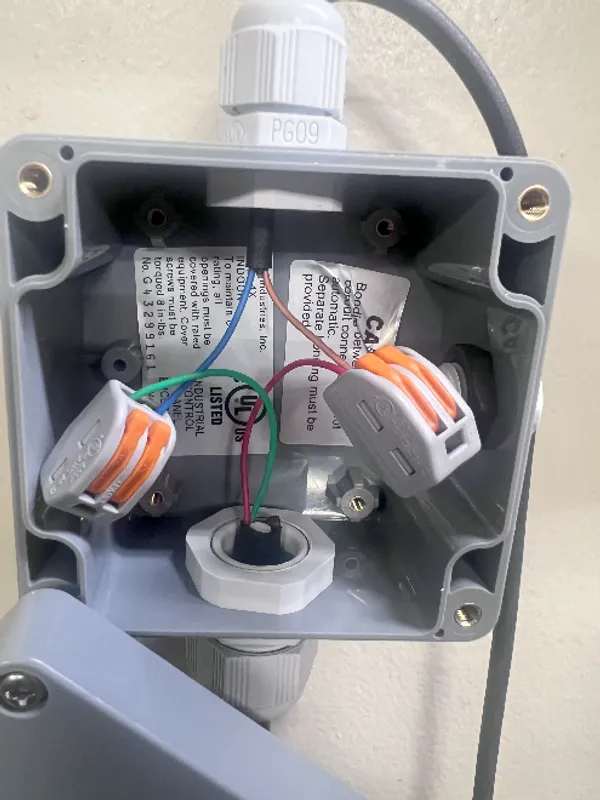

- JUNCTION BOX WIRING:

- Insert Level Sensor cable into grey junction box if it is not already assembled

- Insert flying lead end of M12 cable (one orange end) - terminate to desired length

- Use provided WAGO connectors to wire per below:

- Level Sensor Red wire to >>> BROWN wire on M12 cable

- Level Sensor Green wire >>> BLUE wire in M12 cable

- Yellow wire NOT USED

- Mount Terminal Box in desired location - and router wire convenient for uses

Connect Metalworking Fluid

Section titled “Connect Metalworking Fluid”- Components provided in kit for - View Kit

- Connect with hose kit provided in your shipment.

- Inlet: Connect to fresh coolant

- Return: Return non-mixed fluids to tank. For relief pressure if ever required.

Fluid Inlet and Outlet Connections

Section titled “Fluid Inlet and Outlet Connections”Refer to Infrastructure Plumbing, Overview Diagram and Digital Feed Unit

Internet Connection

Section titled “Internet Connection”- An internet connection is required for the services below to work as intended

- Remote service and troubleshooting

- Machine configuration and operation

- Timely alaerting for warning and faults

- Reports as subscribed (consumption/insight/etc.)

- Uses TSL technology and industry standard encryption technology ensures your data stays protected in transit for complete IoT security.

- Call us if your IT staff has any concerns, we have taken extra steps with external IT consultants to ensure this is a safe and low risk solution.