Piping and Tubing

This guide covers the installation and setup of the base plumbing infrastructure required for the FullShop Gen 3 system, including pipe specifications, layout requirements, and connection points.

Our experience is that the quality of the installation is proportional to the quality of the project management and planning that goes into it. Provide clear directions and instructions for your plumbing crew. Clear communication on where pipe runs, and drop are expected to be installed go a long way to customer satisfaction.

Concepts and Sizing

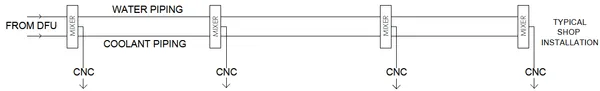

Section titled “Concepts and Sizing”There are two main piping concepts used to install a FullShop Gen 3 solution – See also Best Practices

-

Two header pipes installed from DFU into plant.

- Water Size is typically 1” or 1 ¼”.

- Coolant Size is typically ¾”

-

Single drop from Mix Manifold to CNC for emulsion.

- ½” through ¾” are common sizes.

- Each CNC machine requires its own mixing manifold which is provided in the kit.

The objective is to specify pipe diameters that work with 40 psi inlet pressure to DFU while maintaining 4 gallons per minute (GPM) system flow rate. The reference table below includes +25% for fitting.

Estimated Values for Water and Emulsion at 4 GPM

Section titled “Estimated Values for Water and Emulsion at 4 GPM”| Type | PEX tube diameter (in) | 1 psi loss (ft) | 5 psi loss (ft) | 10 psi loss (ft) | Gallons per 100 feet (gal) |

|---|---|---|---|---|---|

| Drop | ½ | 4 | 21 | 43 | 0.92 |

| Drop | ⅝ | 11 | 53 | 106 | 1.60 |

| Drop | ¾ | 22 | 111 | 222 | 1.83 |

| Header | 1 | 75 | 380 | 760 | 3.03 |

| Header | 1 ¼ | 200 | 975 | 1950 | 4.60 |

Drops from Mix Manifold to CNC Sumps

Section titled “Drops from Mix Manifold to CNC Sumps”- Consider a location near site tubes. These are ideal in many cases.

- If the above is not possible consider where you manually fill.

- When a larger external tank is present this location may work if this is where it depletes.

- Type fill into filtered side of tank when possible.

Best Practices

Section titled “Best Practices”- Our recommendation is PEX-A tubing with expansion fittings

- Our recommendation is do not use brass fitting on the coolant lines or where you have RO/DI water.

- Changes in elevation that could trap air require bleeder installation.

- Shut offs at supply and pump system are suggested for service reasons.

- Better emulsification occurs with ambient temperature water and coolant. Think about your pipe routing, refills and overall volume, which may require additional water tempering.

- Our water flowmeter requires users to provide filtering. Particles must not exceed 0.50mm

- Before connecting water source flush pipes carefully to avoid blocking the water turbine caused by particles from the pipe installation.

- Please review notes about water hardness in Technical Data.